博世安全卡盘

安全卡盘是在收放卷应用中支承料卷和传递扭矩的预设计解决方案。

包含一个自关闭手轮,以防手动关闭被忽视,从而避免无意导致的轴松脱,保障您的操作人员安全。

可采用自动配置,进一步提高安全性,而且可以通过远离夹点的远程激活,来减少设置时间。

Tidland 博世安全卡盘是在收放卷应用中支承料卷和传递扭矩的预设计解决方案。根据所需的安全性和自动化程度,可以选择各种不同选项的安全卡盘。这些多用途安全卡盘能帮助减少设置时间,提高卷放质量,并降低维护成本。

手动安全卡盘采用固定或滑动设计,具有独特的自关闭功能,即使操作员在加载后因疏忽忘记关闭卡盘,也能确保安全性能。高效的承重设计,确保长寿命和平稳旋转。可选的针对MAGPOWR Global系列制动器的可更换插口插件和适配器,应用场合广泛。

可购买或租赁激光校准工具,来排除未校准可能导致带有VT插入件的安全卡盘的振动或磨损问题。请查看下面的安装和操作文档,了解更多信息。

*滑动卡盘轴向调整在50.8 mm至101.6 mm之间,取决于具体的型号。

22-30

| 轴长 | 4.5 in114.3 mm |

|---|---|

| 每对最大卷重 | 1,764 lb800 kg |

| 轴颈方型 | 22至30 mm22至30 mm |

| 扭矩 | 180 Nm180 Nm |

| 速度 | 1,350 rpm1,350 rpm |

| 制动型号 | 200、 205、305T200、 205、305T |

30-40

| 轴长 | 4.5 in114.3 mm |

|---|---|

| 每对最大卷重 | 1,600 kg1,600 kg |

| 轴颈方型 | 30至40 mm30至40 mm |

| 扭矩 | 350 Nm350 Nm |

| 速度 | 1,350 rpm1,350 rpm |

| 制动型号 | 250、305T、380250、305T、380 |

40-50

| 轴长 | 4.5 in114.3 mm |

|---|---|

| 每对最大卷重 | 2,800 kg2,800 kg |

| 轴颈方型 | 40至50 mm40至50 mm |

| 扭矩 | 1,100 Nm1,100 Nm |

| 速度 | 1,350 rpm1,350 rpm |

| 制动型号 | 305T、460305T、460 |

- 包装

- 吊牌标签

- 无纺布

- 特种轮转加工

- 电池

- 纸板

- 药品类包装

- 软包装

- 面巾和纸巾

- 食品和饮料包装

相关产品

D-MAX-E增强型卷材纠偏控制器

紧凑且易于使用的卷筒纸引导控制器,可为各种工业应用提供精确可靠的控制。

外置式气胀轴

我们的外部元件轴采用创新的两件式膨胀元件,可实现令人印象深刻的平衡和扭矩组合,以及自动回缩、耐用的聚乙烯气囊和故障安全多回路空气系统。

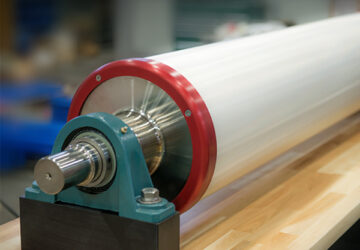

Webex真空辊

独特设计的内部真空系统可对各种材料提供强大、稳定的抓握,确保一致且可靠的卷材处理。

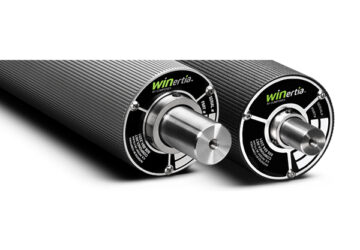

WINertia™ AV – 排气铝合金死轴惰辊

采用特殊的通风口设计,可在苛刻的环境中提供一致、可靠的性能。